Preamble

System error budgets should be developed and analyzed

as an integral part of system designs. System engineers

must determine the necessary levels of accuracy for

system elements such as field sensors, actuators, signal

conditioning modules (SCMs), and controlling units (PCs

and PLCs). In addition, software algorithm integrity and

operating system compatibility, or the degree of software

“openness,” must be included in error budget

considerations. For example, the accuracy and resolution

of software algorithm calculations must be compatible

with measurement accuracy.

In the process of analyzing system accuracy needs, the

topic of resolution requires attention as it relates to overall

accuracy. Oftentimes distinguishing between accuracy

and resolution is misinterpreted in determining system

needs. Some examples and illustrations are presented in

this Application Note in an attempt to show readers that

there is a significant difference between accuracy and

resolution, even though they are related.

Examples

Before launching into some examples, recall how

accuracy is denoted. A reading device that has a specified

accuracy of ±0.015% will actually give a reading that is

between 0.99985 and 1.00015 times the actual value.

Interesting how our standards have defined “accuracy.”

Note here that the ±0.015% number is in reality the

“error.”

Accuracy is the measurement device’s degree of absolute

correctness, whereas resolution is the smallest number

that can be displayed or recorded by the measurement

device. For example, measuring 1 volt within ±0.015%

accuracy requires a 6-digit instrument capable of

displaying five decimal places. The fifth decimal place

represents 10 microvolts, giving this instrument a

resolution of 10 microvolts.

For the following examples, the digital display quantizing

error (±1 bit minimum) in the least significant digit is

assumed to be zero.

Example 1

Suppose one has a voltage source that is known to be

exactly 5.643 volts. Now imagine, if you will, that one

uses a digital voltmeter that is (somehow) 100% accurate,

but has only 3 display digits and is defined as “3-digit

resolution.” The reading would be 5.64 volts. Is the

reading accurate? There was an accurate source and an

accurate voltmeter, yet the reading does not represent the

actual voltage value. Some may say that our 100%

accurate voltmeter gave us a reading error of 3 millivolt

or 0.0532%.

In this hypothetical example, the reading could be

considered in error unless one only wants a 3-digit

reading. In cases where source and instrument accuracy

are 100%, the resolution of the reading instrument and the

acceptance of the observer determine what constitutes

“accuracy.”

Example 2

Again assume a 100% accurate source of 5.643 volts;

however, in this case our 3-digit display digital voltmeter

has a ±0.015% accuracy specification (recall this means

that the displayed value is actually between 0.99985 and

1.00015 times the source value).

In this case, the digital voltmeter still reads 5.64 volts.

One can say that this 0.015% accurate instrument gives a

0.0532% error, as in Example 1. Once again, the

resolution and the observer determine what constitutes

“accuracy.”

Example 3

In this example, consider measuring the precise 5.643-

volt source using a 5-digit display digital voltmeter with a

specified accuracy of ±0.015%. This instrument displays

a reading of between 5.6421 (for 5.64215) and 5.6438 (for

5.64385).

Example 4

Repeat Example 3 using a 6-digit display digital

voltmeter, again with a specified accuracy of ±0.015%.

The display will be between 5.64215 and 5.64385.

Clearly, these examples illustrate that accuracy and

resolution are indeed related, and each situation has to be

evaluated based on the system requirements and the

observer’s acceptance of “error.”

Reality

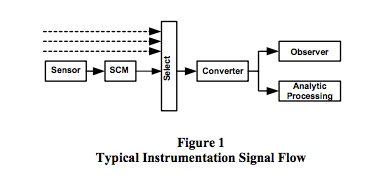

A typical situation is illustrated in Figure 1. As shown,

sensor signals are conditioned with signal conditioning

modules, selected, and then converted into a usable

number either for analytical process control or

observation.

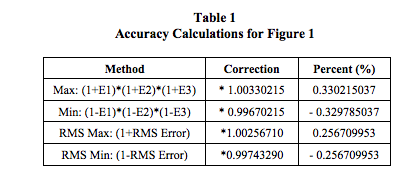

In Figure 1, assume sensors have ±0.25% (E1) accuracy

specifications, SCMs have ±0.03% (E2) accuracy

specifications, and the select-converter function has

±0.05% (E3) net accuracy. Table 1 displays some

different system “accuracy” correction calculations. Since

errors are random and have ± values, RMS calculations

are often used as opposed to the worst case maximum and

minimum. RMS error is defined as the square root of the

sum of each error squared, √ {(E1)2 + (E2)2 + (E3)2 }.

Number values from the converter function in Figure 1

are presented to the observer with a display unit that has

its own error and resolution specifications. In addition, the

analytical processing function imports this numerical

value to use in a complex mathematical operation, which

may be based on an empirical model that achieves results

using computation shortcuts, which in turn have

additional accuracy and resolution specifications.

As is evident, a detail error budget must contain numerous

factors in order to correctly determine “system accuracy.”

Reality Check

Have you ever experienced this scenario or one similar?

Your project manager wanders into your office

(cubicle), makes small talk about how the

control system project is going, and asks if you

and your team have any needs. Before leaving,

he comments that while reviewing your project

purchases he noticed that the ADC module for

the main controller is an 8-channel differential

input unit with 16-bit resolution, which he

thought would give one part in (216 -1) accuracy,

something on the order of 0.0015%. He says he

also noticed that all the SCMs you purchased

were only 0.03%. Politely, he asks you to

explain. You begin your explanation by

pictorially representing one possible ADC

system, as illustrated in Figure 1.

Analog-to-digital converters (ADC) are advertised as

having “n” bit resolution, which often is misunderstood to

mean accuracy. Specifications need to be closely

examined, however, to determine the unit’s true accuracy.

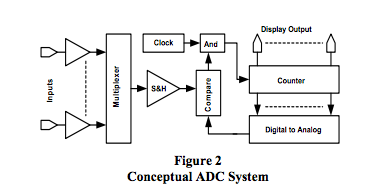

Figure 2 depicts one typical scheme used to convert an

analog signal to a digital representation for computer

manipulations or display. In this typical representation,

semiconductor switches select analog input signals, which

are captured (sampled for a small slice of time) and held

in a sample and hold amplifier function block (SHA).

This SHA function may also contain a programmable gain

function to selectively scale each analog input. Once a

signal slice is captured, an n-bit counter begins to count.

The counter contents are converted to an analog voltage

using switched resistors or current sources. When this

analog signal equals the input SHA signal, counting halts

and the counter contents are made available as a digital

representation of the sampled analog input value. This

process can sample analog inputs at blinding speeds in the

10MHz range to provide digital representations of time

varying analog inputs; it also has numerous sources of

error that collectively degrade true accuracy, which is not

necessarily determined solely by the n-bit resolution

specification.

ADC Error Budget

The following list identifies errors associated with using a

typical ADC scheme such as illustrated in Figure 2.

- Sampling Speed

From Nyquist Sampling Theory, if the analog signal

changes rapidly, then the ADC must sample at least

twice as fast as the changing input. Many applications

use a sampling rate at least 10 times the highest

frequency present in the input signal. Sampling slower

than one-half the signal frequency will result in

inaccurate readings. Most ADC’s sampling speeds are

adequate for slow varying process control signals.

See Reference 2 for more details on this topic.

- Input Multiplexed Errors

The input multiplexer circuit may have OpAmp

buffers on each input line that could introduce errors

such as in voltage offset, current bias, and linearity. In

addition (and more common) are the two major

multiplexer errors: (a) cross talk between channels,

i.e., the signal from an “on” channel leaks current into

the “off” channels, and (b) signal reduction through

voltage division caused by the finite non-zero

resistance of the semiconductor switches and the finite

input impedance of the circuitry that follows.

- Sample and Hold Amplifier (SHA)

This function is an OpAmp based circuit with

capacitive components all designed to switch, buffer,

and hold the sampled analog voltage value.

Consequently, there will be linearity, gain, powersupply

rejection ratio (PSRR), voltage offset, charge

injection, and input bias current errors. For a detail

analysis of typical OpAmp errors, see Dataforth’s

Application Note AN102, Reference 3.

- Converter

In the counter, comparator, and ADC circuit there are

such errors as overall linearity, quantizing error

(defined as uncertainty in the least significant bit

[LSB], typically ±1/2 LSB), and PSRR.

- Temperature

All analog circuit functions within the ADC unit are

subject to temperature errors and hence an overall

temperature error specification is assigned to an ADC.

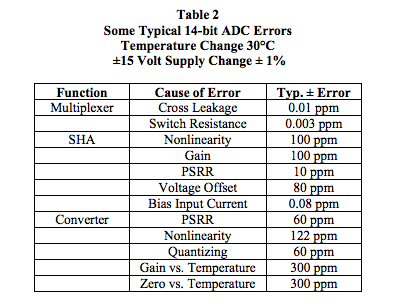

Table 2 identifies some of the internal errors associated

with a typical ADC. Data was taken from various analogto-digital

converter manufacturers. This table is by no

means a complete ADC error analysis; the values shown

illustrate that there are internal errors that collectively

contribute to the definition of an ADC’s overall accuracy.

An algebraic sum model on these errors suggests a ±0.1%

error for this 14-bit ADC, whereas the RMS sum model

suggests a ±0.05 % error. Resolution alone erroneously

implies ±0.006%. These internal ADC error numbers used

in either an algebraic or RMS summing model clearly

illustrate that the net effective accuracy of an n-bit ADC

is not equal to the ADC resolution, defined as

approximately 1/(2n -1). To determine actual ADC

accuracy, the manufacturer’s ADC specifications should

always be carefully examined.

Note: Industrial sensors used in process control and data

acquisition systems can have accuracies that are much

less than SCMs or ADC units and often dominate errors

in a total system error budget. Dataforth SCMs have

accuracies that typically exceed both those of industrial

sensors and ADC modules. Readers are encouraged to

examine Dataforth’s complete line of SCM products. See

Reference 1.

Dataforth References

- Dataforth Corp. Website

http://www.dataforth.com

- Dataforth Corp., Application Note AN112

http://liwww.dataforth.com/technical_lit.html

- Dataforth Corp. Excel Interactive Workbook

for 2-Pole LP Active Filter

http://liwww.dataforth.com/catalog/pdf/an113.xls